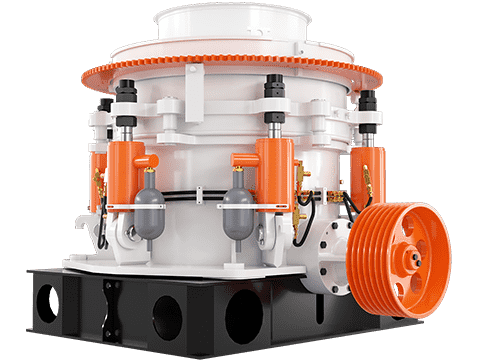

Hydraulic Cone Crusher Introduction

HP Hydraulic Cone Crusher is a high-performance cone crusher which is designed by adopting foreign advanced design concepts and combining the performance of domestic metal materials. The machine adopts a special crushing cavity which is designed by the principle of inter-granular lamination and the matching speed, instead of the traditional single-particle crushing principle, to achieve selective crushing of materials, with uniform crushing particle size and good particle shape

Images

Advantages

During the installation and running the equipment, a buffer silo and variable frequency feeding equipment should be equipped to ensure continuously feeding and full cavity stable feeding. Realize the adjustable and controllable feeding of the equipment.

Working Principles

When working, the motor drives the transmission shaft to rotate, the transmission shaft drives the eccentric sleeve to rotate around the eccentric shaft through the large and small bevel gears, and then the eccentric shaft drives the moving cone to swing eccentrically.

Technical parameters

Contact usContact us for any item you want by filling out the form below

Contact usContact us for any item you want by filling out the form below

Email:

Email:

10-350mm

10-350mm  50-1200t/h

50-1200t/h

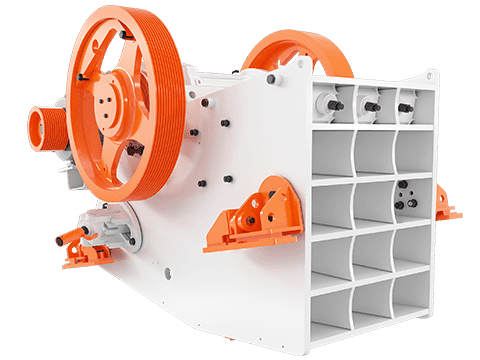

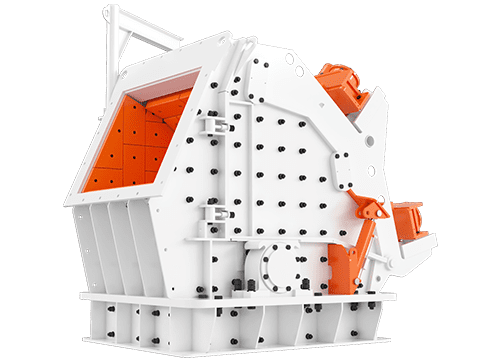

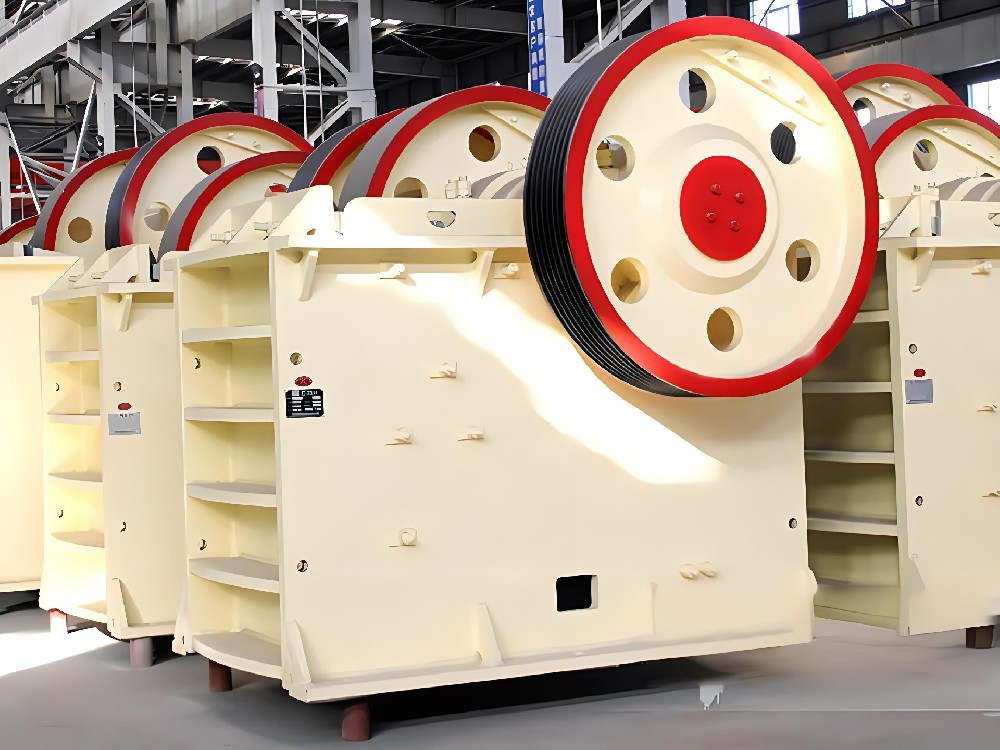

Popular items

Popular items

Whatsapp

Whatsapp Mobile

Mobile Message

Message