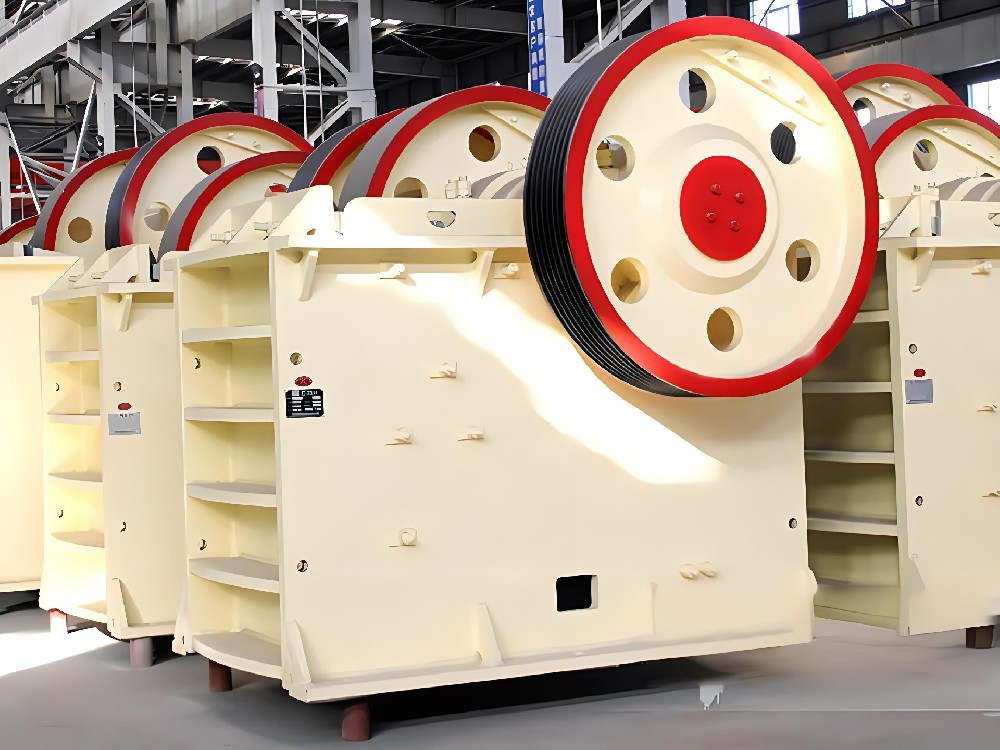

PE 500*750 cobble jaw stone crusher Introduction

Jaw crusher are typically used as primary crushers, or the first step in the process of reducing rock.

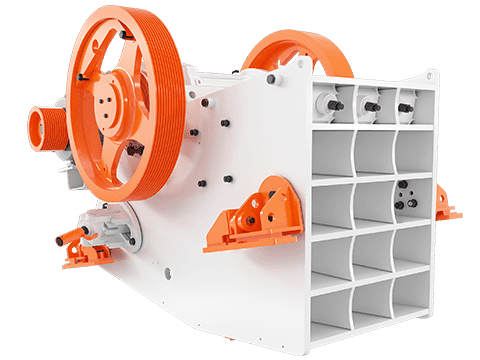

The 500*750 jaw crusher comprises several key components that contribute to its functionality and performance. These components typically include:

1. **Frame**: The robust frame provides structural support for the crusher and houses the various components.

2. **Eccentric Shaft and Bearings**: The eccentric shaft transmits the rotational motion of the motor to the movable jaw, facilitating the crushing process. Bearings support the shaft's rotation, ensuring smooth operation.

3. **Movable Jaw Plate**: This crucial component moves back and forth, enabling the crushing action as it presses against the fixed jaw plate.

4. **Fixed Jaw Plate**: Positioned opposite the movable jaw, the fixed jaw plate provides a surface against which the material is crushed by the movable jaw.

5. **Toggle Plate**: The toggle plate plays a pivotal role in the jaw crusher's operation, providing support and safety during the crushing process.

6. **Adjustment Device**: This feature allows for the adjustment of the discharge opening, controlling the size of the crushed material.

7. **Wedge Block**: The wedge block facilitates the adjustment of the discharge opening by moving the movable jaw plate towards the fixed jaw plate.

8. **Tension Rod**: This component applies tension to the toggle plate, providing the necessary support for the crusher's operation.

These components work in unison to enable the 500*750 jaw crusher to effectively crush various materials, making it an indispensable piece of equipment in industries such as mining, construction, and metallurgy.

Product Application

1. Jaw crusher is mainly used for the medium and fine crushing of hard ores and rocks in metallurgy industry, mine industry, chemical industry, cement industry, construction industry, refractory materials industry and ceramic industry and other sectors.

2. Jaw crusher suitable for crushing all kinds of hard and soft ores with less than 300MPa compressive strength, such as pebble, calcite, granite, quartz, concrete, dolomite, blue stone, iron ore, limestone, iron ore, coal gaungue, construction waste, ferrosilicon, basalt, sandstone, ore, glass, cement clinker, rock salt lump and etc.

We are a professional manufacturer of crushers. I would like to give you a suggestion to all bosses. Only by purchasing equipment from manufacturers can you have worry-free after-sales service. Later accessories are easier to purchase, saving cost and time.

To choose a suitable model for you , you need to tell us :

1.what kind of stone do you want to crush ?

2. what's the size of your stone before crush ? how many inch or mm ?

3. what's your requirements of final product size ? how many inch or mm ?

4. what's your requirements of production capacity ? how many ton per hour ?

Please contact us with your detailed requirements, we will send you accurate quotation and extra discounts.

Images

Advantages

The PE500*750 jaw crusher offers several advantages, including:

1. **High Crushing Ratio**: It is known for its high crushing ratio, which means it can efficiently crush large-sized materials into smaller, more manageable pieces.

2. **Reliable Performance**: This type of jaw crusher is recognized for its reliable performance, providing consistent operation and productivity.

3. **Wide Application Range**: The PE500*750 jaw crusher is versatile and suitable for crushing various materials with a wide range of hardness and abrasiveness, making it applicable to different industries and applications.

4. **Robust Construction**: It is built with a sturdy and durable construction, capable of withstanding the rigors of heavy-duty usage in demanding environments.

5. **Adjustable Discharge Opening**: The ability to adjust the discharge opening allows for flexibility in controlling the size of the crushed material, catering to specific requirements.

6. **Energy Efficient**: It is designed to be energy efficient, contributing to cost-effective operation and reduced energy consumption.

These advantages make the PE500*750 jaw crusher a valuable asset in industries such as mining, construction, and quarrying, where reliable and efficient crushing equipment is essential.

Working Principles

Technical parameters

Model:PE500*750

Feeding size(mm):<=425

Output size(mm):50-100

Capacity(t/h):40-110

Motor power: 55kw

Contact usContact us for any item you want by filling out the form below

Contact usContact us for any item you want by filling out the form below

Email:

Email:

capacity:50-100t//h

capacity:50-100t//h  feeding size:<=425mm

feeding size:<=425mm

Popular items

Popular items

Whatsapp

Whatsapp Mobile

Mobile Message

Message