Jaw Crusher

Jaw Crusher, comsists of primary jaw crusher and secondary jaw crusher, which is the most widely used crushing equipment for almost all kinds of chemicals, stones and ores, such as grantie, basalt, river pebbles, limestone, white fused alumina, wfa, brown fused alumina, basault, calcite, and so on.

With the unique structure and wide throughput range, jaw crusher can be used for primary and fine crushing of over 120 kinds of stones and ores in mining, quarry, construction and other fields.

Max input size: 20-1200mm

Capacity:3-1600 t/h

✅ Over 30 years of manufacturing experience

✅ Customized plant design available

✅ In-stock machines and fast delivery

✅ ISO-certified and CE-marked equipment

✅ Exported to over 30 countries worldwide

One-stop solution and commitment to quality & service.

When it comes to primary crushing solutions for hard and abrasive materials like granite, basalt, river stone, and construction debris, few machines are as reliable and versatile as the jaw crusher. At MINGYUAN, we offer a complete lineup of jaw crushers, including stationary jaw crushers, mobile jaw crushers, and complete crushing plants that are designed to deliver powerful performance and long-term reliability.

Whether you’re setting up a quarry, recycling construction waste, or processing raw minerals, MINGYUAN has the right jaw crusher for you.

✅ Why Choose MINGYUAN as Your Jaw Crusher Manufacturer?

MINGYUAN has been manufacturing jaw crushers and stone crushing equipment for over 30 years. We are known not just for the quality of our machines, but for our customer-centric approach and ability to offer tailor-made solutions for your specific needs.

🔧 Key advantages of MINGYUAN jaw crushers:

✅ ISO and CE certified equipment

✅ Factory-direct jaw crusher prices

✅ Tailored design upon request

✅ Full service: design, manufacturing, shipping, installation & training

✅ After-sales support with spare parts and maintenance

🔍 What is a Jaw Crusher?

A jaw crusher is a type of stone crushing equipment that uses compressive force to break down large materials into smaller sizes. The working mechanism involves a fixed jaw and a moving jaw. As the moving jaw compresses the material against the fixed jaw, it crushes and reduces it.

This design makes jaw crushers particularly effective for:

Primary crushing in mineral and quarry applications

Processing abrasive materials like granite and quartz

Reducing construction and demolition debris

🏭 Types of MINGYUAN Jaw Crushers

MINGYUAN produces various types of jaw crushers to meet different crushing requirements.

1️⃣ Stationary Jaw Crusher

Our standard jaw crusher models are designed for fixed crushing plants and offer high efficiency, durability, and large feed opening sizes.

Features:

Feed size: up to 900 mm

Capacity: 5 – 800 tons per hour

Simple structure, easy maintenance

Heavy-duty cast steel frame

Energy-efficient operation

These crushers are perfect for mining operations, cement plants, and large-scale aggregates production.

2️⃣ Mobile Jaw Crusher

For maximum flexibility on job sites, MINGYUAN also offers mobile jaw crushers, available in wheel-mounted or track-mounted versions.

Key benefits:

Easy to transport and set up

Self-contained unit with generator (optional)

Suitable for remote or urban jobsites

Quick deployment for small or medium crushing projects

Mobile jaw crushers are widely used in road construction, demolition sites, and temporary quarry operations.

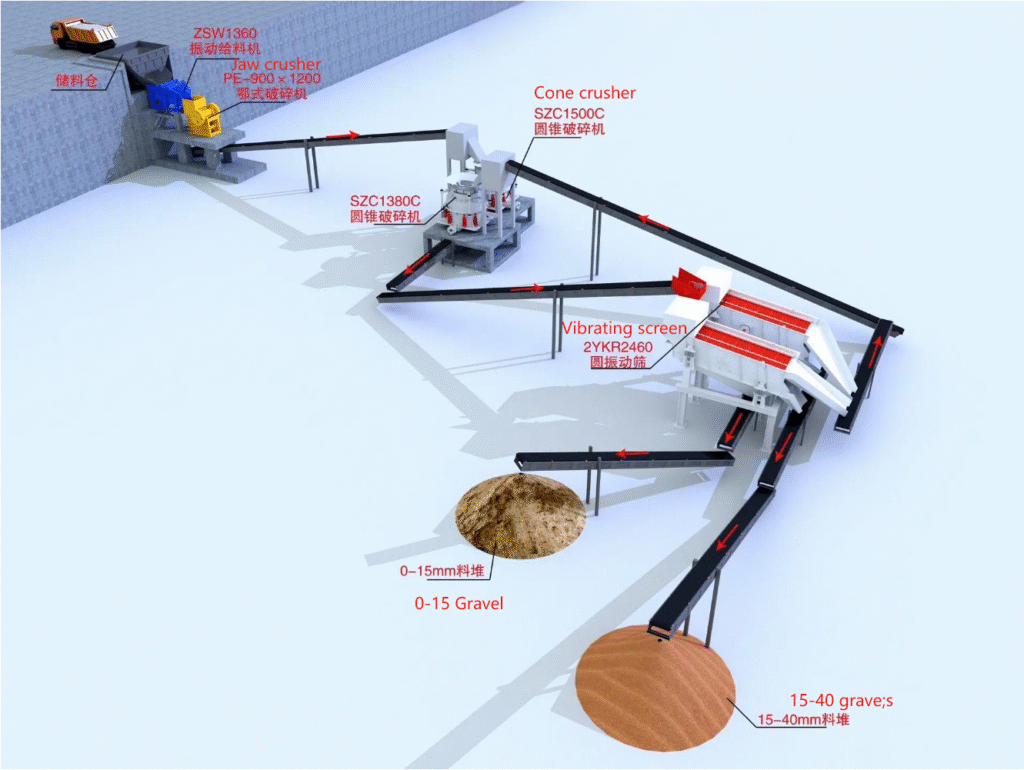

3️⃣ Complete Jaw Crusher Plant

MINGYUAN offers complete crushing plants that include:

Vibrating feeder

Jaw crusher

Belt conveyor

Vibrating screen

Control system

Optional: secondary crushers, dust collectors, etc.

We can customize plant capacity from 10 tph to 500 tph, based on your material, budget, and layout requirements.

💰 Jaw Crusher Price — What to Expect

One of the biggest advantages of choosing MINGYUAN is our factory-direct pricing. Since we manufacture everything in-house, we can offer better prices without compromising quality.

💵 Typical price ranges:

Small jaw crusher (PE150x250 to PE250x400): $1,500 – $4,000

Medium jaw crusher (PE400x600 to PE600x900): $4,500 – $12,000

Large jaw crusher (PE750x1060 to PE1000x1200): $15,000 – $40,000

Mobile jaw crusher units: $20,000 – $75,000 depending on configuration

Note: Prices may vary based on motor type, control system, chassis design, and customizations.

For a free quote, contact our team with your required feed size, final output size, and production capacity.

📦 Jaw Crusher for Sale — Available Models

MINGYUAN offers jaw crushers under both PE (primary crushing) and PEX (fine crushing) series.

Model | Size of Feed Opening(mm) | Max Feed Size (mm) | Discharge Range Opening (mm) | Capacity (m3/h) | Motor Power (kw) |

PE-250×400 | 250×400 | 210 | 20-60 | 3-13 | 15 |

PE-400×600 | 400×600 | 340 | 40-100 | 10-35 | 30 |

PE-500×750 | 500×750 | 425 | 50-100 | 25-60 | 55 |

PE-600×900 | 600×900 | 500 | 65-180 | 30-85 | 55- 75 |

PE-750×1060 | 750×1060 | 630 | 80-180 | 72-150 | 110 |

PE-800×1060 | 800×1060 | 680 | 100-200 | 85-143 | 110 |

PE-870×1060 | 870×1060 | 750 | 170-270 | 145-235 | 110 |

PE-900×1060 | 900×1060 | 780 | 200-290 | 170-250 | 110 |

PE-900×1200 | 900×1200 | 780 | 95-225 | 100-240 | 110 |

PE-1000×1200 | 1000×1200 | 850 | 195-280 | 190-275 | 110 |

PE-1200×1500 | 1200×1500 | 1020 | 150-300 | 250-500 | 160 |

PEX-150×750 | 150×750 | 120 | 18-48 | 5-16 | 15 |

PEX-250×750 | 250×750 | 210 | 25-60 | 8-22 | 22 |

PEX-250×1000 | 250×1000 | 210 | 25-60 | 10-32 | 30-37 |

PEX-250×1200 | 250×1200 | 210 | 25-60 | 13-38 | 37 |

PEX-300×1300 | 300×1300 | 250 | 20-90 | 10-65 | 75 |

Custom sizes and configurations are available upon request.

🌍 Applications of MINGYUAN Jaw Crushers

Our jaw crushers are widely used in industries such as:

Mining and mineral processing

Construction and infrastructure

Cement and concrete recycling

Highway and railway building

Metallurgy and chemical engineering

They are suitable for crushing:

Granite

Basalt

Limestone

Quartz

Iron ore

Copper ore

Construction debris

🛠️ Jaw Crusher Plant Case Studies

✅ 100 TPH Limestone Crushing Plant – Philippines

Equipment: PE500x750 jaw crusher + impact crusher + screen

Outcome: High-quality aggregates for road construction

✅ 200 TPH Granite Plant – Nigeria

Equipment: Mobile jaw + cone crusher + screen

Outcome: Reduced project cost and faster installation

✅ Small-Scale Mining – Kenya

Equipment: Diesel-powered PE250x400 jaw crusher

Outcome: Efficient crushing at remote gold mining site

🧰 Jaw Crusher Accessories & Spare Parts

MINGYUAN provides all necessary parts for smooth operation:

Jaw plates (Mn13Cr2, Mn18Cr2)

Toggle plates

Bearings and flywheels

Electric motors (Chinese or Siemens)

V-belts and pulleys

All spare parts are kept in stock for fast shipping.

📞 Ready to Get Your Jaw Crusher?

Whether you’re starting a new project or upgrading your equipment, MINGYUAN can provide:

Fixed or mobile jaw crushers

Full plant design

Tailored quotes and delivery

Installation guidance and training

🎯 Contact us today to discuss your crushing requirements. We’ll match you with the right jaw crusher model — at the right price.

🔚 Conclusion

A jaw crusher is often the first step in material processing — and choosing the right one makes all the difference. With MINGYUAN, you get a durable, efficient, and cost-effective machine backed by decades of engineering and after-sales support.

Whether you need a simple mobile jaw crusher for a temporary jobsite or a complete crushing plant for permanent installation, MINGYUAN is your one-stop jaw crusher solution provider.

📩 Contact us now to get your free quote.