Crawler Mobile Screener

Cralwer Mobile Screener

The Crawler Mobile Screener, also referred to as a crawler mobile vibrating screen, is a cutting-edge, self-propelled screening equipment engineered for efficient material separation in dynamic industrial settings. Designed to combine mobility, flexibility, and high performance, this machine is widely used in mining, construction, aggregates, and recycling industries to classify bulk materials such as ores, gravel, coal, and demolition waste into precise particle sizes.

Key Applications

- Mining: Screening ores post-crushing to optimize mineral recovery.

- Construction: Classifying aggregates for concrete production or roadbase materials.

- Recycling: Separating demolition debris into reusable fractions (e.g., concrete, asphalt).

- Quarrying: Processing limestone, granite, or sandstone into graded products.

- Ideal for operations requiring on-the-go screening without compromising precision, the crawler mobile screener empowers businesses to enhance productivity, reduce material waste, and adapt quickly to evolving job site demands.

MINGYUAN Track Mobile Screener: Versatile Screening on the Move

In today’s fast-paced industries, the demand for mobile, flexible, and high-efficiency screening equipment continues to grow. MINGYUAN, a leading manufacturer in crushing and screening solutions, proudly presents its Track Mobile Screener Series, also known as Track Mobile Vibrating Screen, Track Mounted Mobile Screener, or Track Mobile Vibrating Sieve. Designed with mobility, performance, and adaptability in mind, this series provides superior screening capabilities for aggregates, construction waste, minerals, coal, and more.

Whether you are operating in quarrying, mining, recycling, or construction, MINGYUAN’s Track Mobile Screener gives you the edge to process materials directly at the source—no hauling required.

What is a Track Mobile Screener?

A Track Mobile Screener is a piece of mobile equipment mounted on crawler tracks that can be easily moved across worksites. It includes a vibrating screen mechanism that separates materials by size through a series of screens. The screener can be equipped with one, two, or even three layers of mesh screens, depending on the application.

Key Characteristics:

Mounted on crawler-type tracks for excellent terrain mobility

Self-powered with onboard diesel engine or electric motor

Integrated vibrating screen system for effective material separation

Easy transport and setup for remote or shifting job sites

MINGYUAN’s mobile screeners combine rugged construction with advanced screening technology, providing powerful performance in a compact footprint.

Benefits of the MINGYUAN Track Mobile Screener

1. Mobility and Flexibility

Thanks to its crawler track chassis, the screener can move across uneven surfaces, muddy conditions, and hard-to-reach sites without external towing equipment. You can position it directly where materials need to be screened.

2. Time and Cost Efficiency

Reduce material transport and loading times. By screening materials directly at the excavation or demolition site, operators cut fuel costs, reduce machine hours, and eliminate redundant transport logistics.

3. Multi-Material Compatibility

Whether you’re handling crushed stone, sand, gravel, topsoil, coal, or recycling waste, the MINGYUAN Track Screener is designed to screen efficiently in various conditions.

4. Compact and User-Friendly Design

MINGYUAN mobile screeners feature intuitive controls, quick-deploy legs, and accessible maintenance zones. Operators of all experience levels can quickly learn to operate and maintain the unit.

5. Custom Configurations

Choose between single, double, or triple deck configurations, as well as screen mesh sizes, conveyor discharge heights, hopper designs, and more.

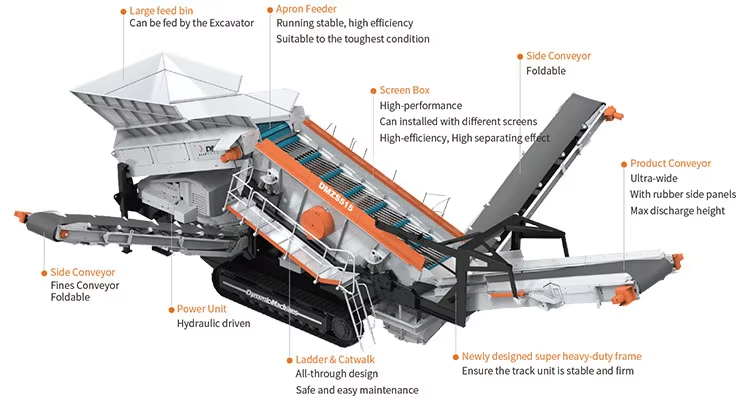

Core Components and Working Principle

A typical MINGYUAN Track Mobile Screener consists of:

Crawler Chassis: Provides mobility across rugged terrain.

Feed Hopper: Large capacity hopper that accepts material directly from excavators, loaders, or crushers.

Vibrating Screen Box: The heart of the unit where material is stratified and separated.

Discharge Conveyors: Conveyors carry the different-sized screened materials to stockpiles or further processing units.

Power System: Diesel engine or optional electric drive.

Working Principle:

Material is fed into the vibrating screen box.

As the box vibrates, particles are sorted through the mesh screens.

Oversized material moves off the top screen, while undersized materials fall to lower decks or through the bottom.

Each screened size is transported by a separate conveyor.

Typical Applications

MINGYUAN Track Mobile Screeners are used in a wide variety of industrial applications:

1. Quarrying and Mining

Aggregate screening

Pre-screening before crushing

Sizing minerals

2. Construction and Demolition (C&D) Waste

Concrete, brick, and asphalt recycling

Soil remediation

Material separation on demolition sites

3. Recycling Industry

Plastic, glass, and metal separation

Biomass and compost screening

4. Coal and Energy

Screening of coal lumps and fines

Sizing of biofuel and biomass

5. Agriculture and Landscaping

Topsoil screening

Mulch and compost sizing

Advantages of Choosing MINGYUAN Track Mobile Screener

Robust Engineering Each unit is built with heavy-duty materials and high-torque vibrating motors for long-lasting durability.

Environmentally Friendly Options Models are available with low-emission engines or full electric drive to comply with local environmental regulations.

Easy Transport and Deployment Compact dimensions allow for easy transport via low-bed trailer. On-site setup can be completed within minutes.

After-Sales Support MINGYUAN offers comprehensive training, spare parts availability, remote assistance, and onsite support.

Custom Manufacturing Our design team works with clients to develop specialized screeners for unique material types, climate conditions, and production layouts.

Sample Technical Specifications

| Model | Decks | Capacity (t/h) | Screen Size (mm) | Power (kW) | Weight (t) |

|---|---|---|---|---|---|

| MTS-1540 | 2 | 80 – 150 | 1500 x 4000 | 55 | 20 |

| MTS-2060 | 3 | 150 – 250 | 2000 x 6000 | 75 | 32 |

| MTS-1235 | 1 | 50 – 100 | 1200 x 3500 | 45 | 17 |

Note: Custom designs available based on application.

Integration with Crushing and Screening Lines

MINGYUAN’s Track Mobile Screeners can operate independently or as part of a complete mobile crushing and screening system. When paired with MINGYUAN mobile crushers (jaw crusher, impact crusher, or cone crusher), they create a full mobile processing solution ideal for fast-moving construction and mining operations.

Quality Control and Certifications

MINGYUAN adheres to international manufacturing standards and implements stringent quality control measures. All units are:

ISO 9001 certified

CE certified for European markets

Subjected to pre-shipment testing and inspections

Customer Testimonials

“We used the MINGYUAN Track Mobile Screener on a limestone project, and it performed above expectations. Set up took under 30 minutes, and we screened 200 tons per hour with no issues.” — Project Manager, Quarry Site in Southeast Asia

“Our demolition crew saved thousands by screening materials directly on site. The MINGYUAN screener was rugged, efficient, and easy to maintain.” — Site Supervisor, Urban Demolition Firm

Conclusion

The MINGYUAN Track Mobile Screener Series offers a flexible, mobile, and efficient screening solution for modern material handling needs. From rugged mining environments to urban recycling centers, this equipment delivers reliable performance with the ability to go wherever your materials are.

For a robust screening solution that goes the distance, trust in MINGYUAN.

Contact us today to learn more about customization options, available models, and pricing.

MINGYUAN — Your Partner for Mobile Screening Innovation.